Welding is a known process in every manufacturing industry. Joining different parts plays a crucial role in the formation of the materials. The quality of the joining is important is ensuring a quality product. But joining plastic parts together is often a tough task. Though bolts and adhesives are common joining products, these often result in ugly plastic joints that require reworking.

Ultrasound happens to be one of the most effective processes for welding plastic material. This process effectively joins plastic parts by high-frequency acoustic vibration. It is a process that welds plastic parts in a quick yet safe and reliable way. This is why ultrasonic plastic welding machine (เครื่องเชื่อมอัลตร้าโซนิค, term in Thai) has become the choice of many industries in joining their plastic materials. This process is effective for thermoplastic applications and not for all kinds of applications.

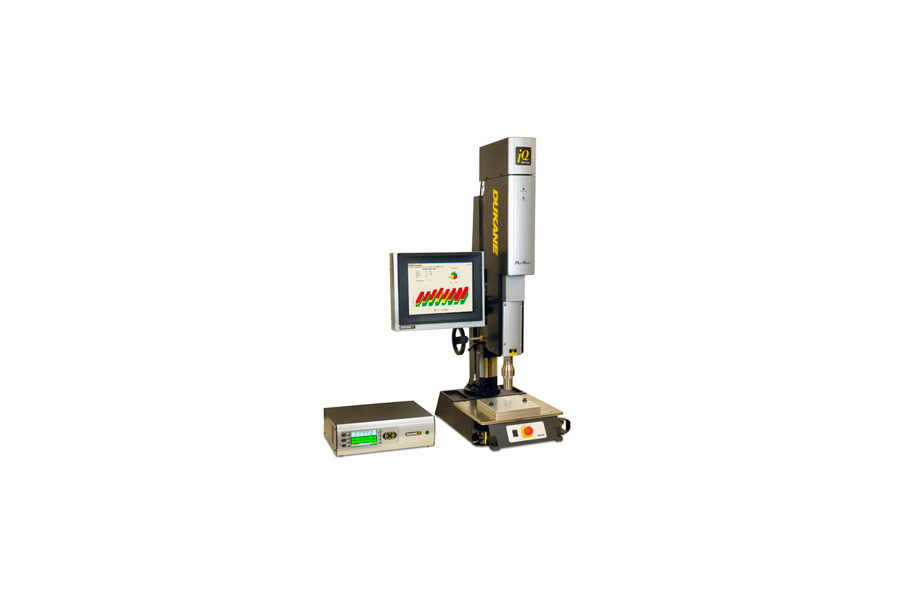

USW

This welding technique is also known by the acronym USW. Mechanical vibration is used to weld two pieces of plastics. This energy causes the parts to deform and create a solid weld. This technique is used by the computer electronic industry, automotive industry, aerospace industry, medical industry, packaging industry, and consumer products industry.

Speed

Speed happens to be one of the most important requirements of the modern world. There is barely any time to waste or put behind a single thing. Ultrasonic welding meets this requirement of speed. These process welds two different thermoplastic parts by sending the high-frequency vibration through the part called the horn. The process makes the materials heat, weld, and cool down fast enough. Sometimes the process just takes a few seconds to get completed. This process allows short turnaround times and high throughput.

Safety

Compared to any other welding technique, ultrasonic welding is safer. The energy is highly targeted which removes the dangers caused by excessive electrical energy. The heat that is produced during the process is also localized and minimal. This allows better safety from damages caused by excessive heat. Localized heat does not impact the other parts of the materials or the machinery.

Reliability

Assembled and tested ultrasonic welding equipment works more reliably than any other welding equipment. The process can also be automated making it easier to join thousands of parts with just minimal human intervention. Reliable welding results in lesser chances of faulty welds and equipment failure. It also produces precise and clean joints when used properly. There is no deformation or plastic flash. The seam is one that is almost invisible and requires no touch-up.

Flexibility

Thermoplastic can be efficiently joined with the help of ultrasonic technology. But this is not the only material that can be joined using this tech. there are quite a few materials which can also be welded by this technique. It can join dissimilar materials efficiently, joining thin and thick combinations without any problem. Completing the job in a small amount of time reliably and without any damage to the machine or materials or fault has made this technique such a favorite to the manufacturing industry.